Spiral Pipe

Annual production capacity: 380.000 tons

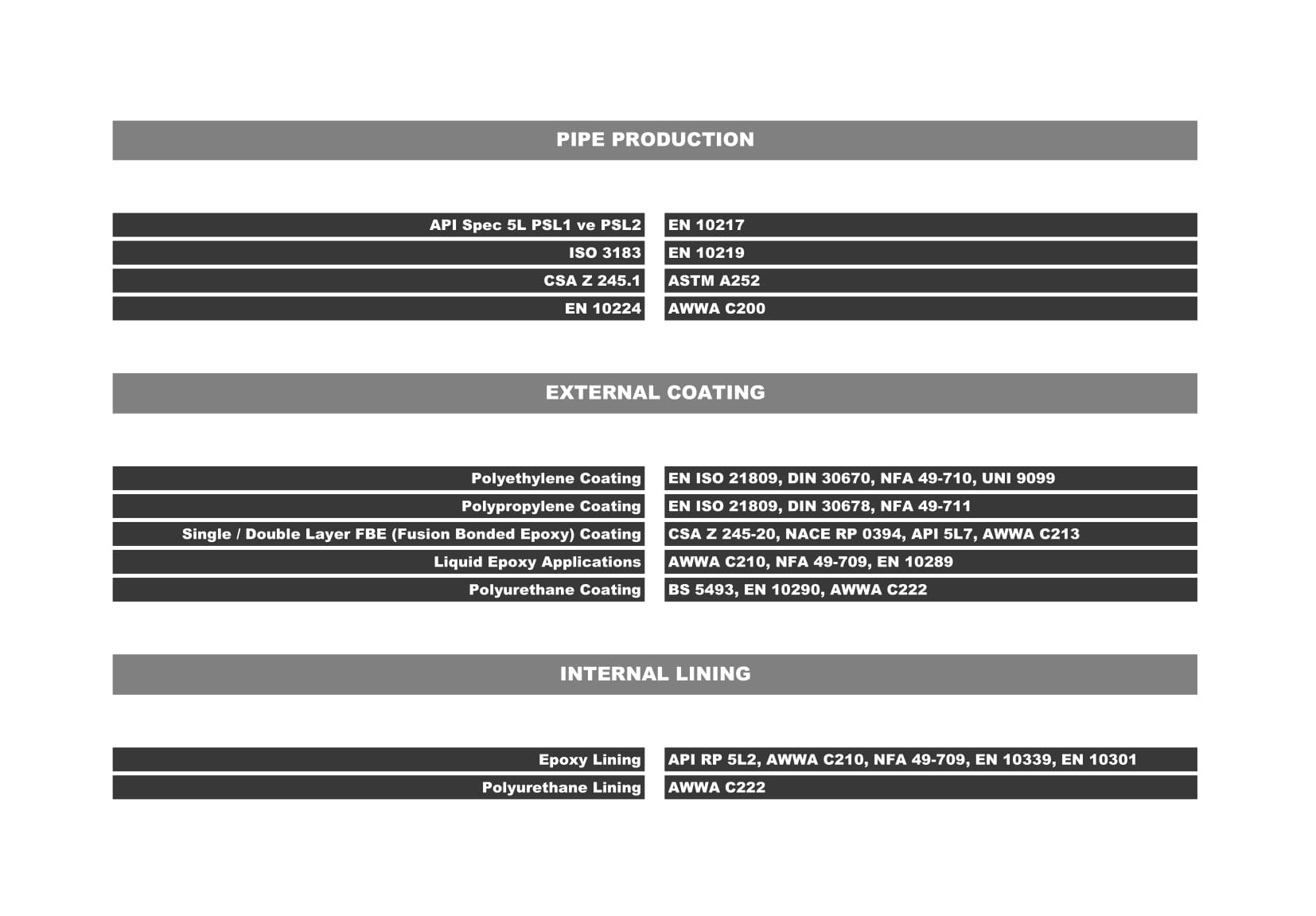

Spiral Pipe Unit is capable to make bare pipe production and coating – lining application of spiral welded steel pipes conform to ; API, API Q1, ISO, EN, DIN, NFA, AWWA, BS and other international well known standards. Our production efficiency has been homologated and certified by all international accreditation associations.

Spiral Pipe Unit is verified via 3rd party inspection agencies by periodic audits. According to the project requirements, Tosyali Algeria Spiral Pipe unit may supply pipes for any kind of domestic and international projects,

Pipe production variety :

- Natural Gas & Petroleum Pipes

- Water Pipes

- Port Piling Pipes

Production Range:

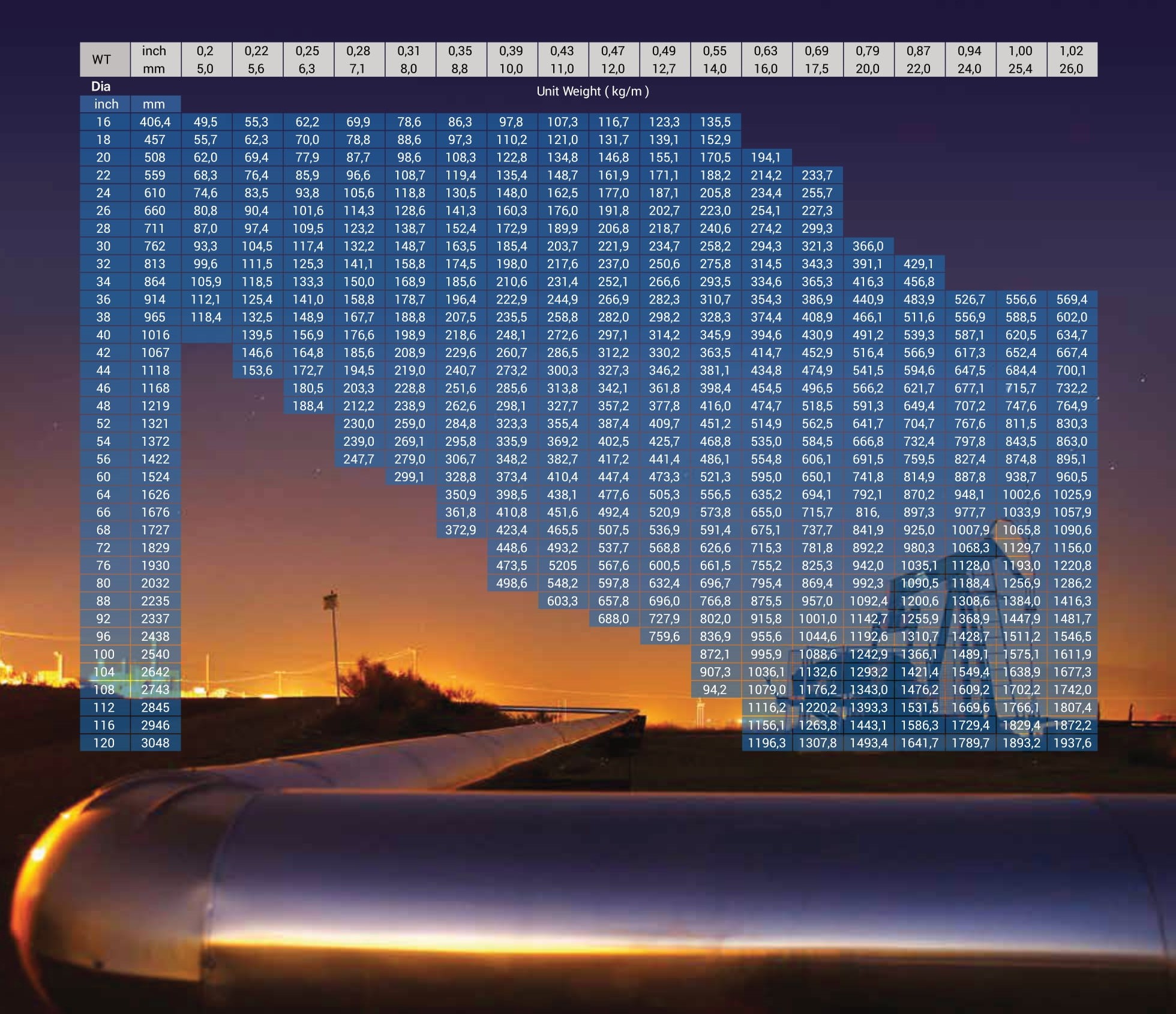

- Diameter: 16 – 120 inch (406,4 – 3.048mm)

- Wall Thickness: 0,2 – 1,02 inch (5 – 26mm)

External Coating:

- Three-Layer Polyethylene (3LPE)

- Three-Layer Polypropylene (3LPP)

- Polyurethane (PU)

- Glass Flake Epoxy (GFE)

- Fusion Bonded Epoxy (FBE)

- Coal Tar Epoxy (CTE)

- Other Epoxy Coatings

Internal Lining:

- Solvent Free Epoxy (SFE)

- Flow Coat Epoxy (FCE)

- Other Epoxy Linings

Pipes are produced in a diameter range of 16 to 120 inches.

Our pipes range in thickness from 0.2 inches (5 mm) to 1.02 inches (26 mm).

Our steel pipes are produced in accordance with national and international production standarts, depending on the project.

Tosyali Algeria tests, inspects and confirms the conformity of the product according to the standarts and project specification at each production stage.

Pipes are coated with different materials according to the customer's usage and demand.

The robotic online pipe monitoring system performs external and internal markings for easy and reliable pipe identification.